We Clean Stuff, We Move Stuff, We Store Stuff: The Simple Secrets to Smarter Automation

- John Stikes

- Nov 18, 2025

- 5 min read

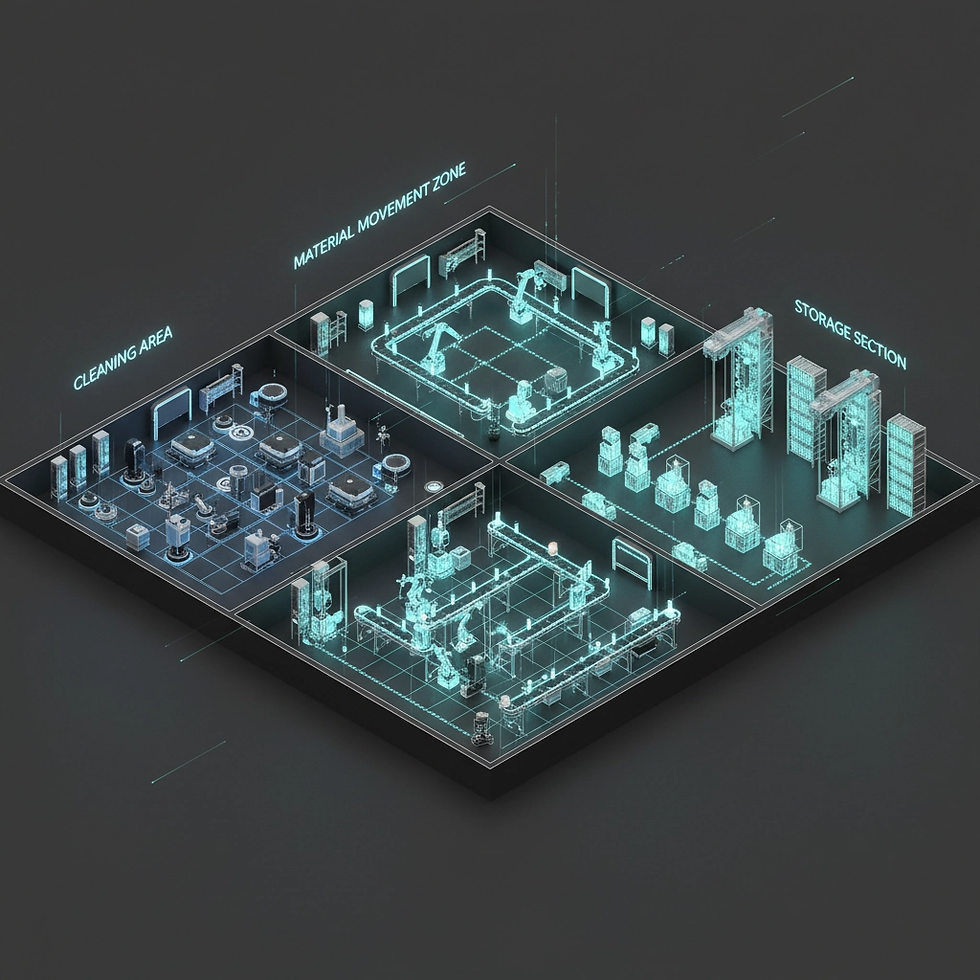

Look, automation doesn't have to be complicated. At its core, most of what happens in a production facility or warehouse boils down to three basic activities: we clean stuff, we move stuff, and we store stuff.

That's it.

Sure, you can dress it up with fancy terminology about "integrated material handling ecosystems" and "advanced automated storage and retrieval architectures," but when you strip away all the jargon, we're really just talking about making these three fundamental tasks work better.

The secret isn't in trying to automate everything at once. It's in picking one of these three areas and starting there.

Why Starting Small Beats Going Big

Most companies think automation means ripping out their entire operation and installing some massive, complex system that costs more than a small country's GDP. That's the old way of thinking, and it's exactly why so many automation projects fail.

The smarter approach? Pick one thing that's driving everyone crazy and fix that first.

Maybe it's spending two hours every morning cleaning the production floor. Maybe it's watching your best maintenance tech waste half his day hunting down parts. Or maybe it's that storage room that's become a game of industrial Tetris where finding anything takes forever.

Start there. Get that working. Then move to the next thing.

The Cleaning Revolution (Yes, Really)

Let's talk about cleaning first, because it's probably the most underestimated automation opportunity in your facility.

Think about it: how much time does your team spend pushing mops around? Sweeping up debris? Emptying trash cans? It's mind-numbing work that nobody really wants to do, but it has to get done.

Enter robotic floor scrubbers. These aren't the clunky, expensive machines from ten years ago. Modern cleaning robots navigate autonomously, avoid obstacles, and deliver consistent results without babysitting. They're perfect for those big, open areas where the same cleaning routine happens every day.

But here's where it gets interesting: cleaning automation isn't just about the floors. Smart facilities are automating the cleaning of their automation equipment too. Sensor cleaning stations automatically remove dust from robot sensors, extending equipment life and maintaining performance. It's automation maintaining automation: and it actually saves money on maintenance costs.

The best part? You can schedule everything digitally. No more paper checklists, no more wondering if the third shift actually cleaned the loading dock. Real-time tracking shows you exactly what got done and when.

Moving Smart: From Carts to Full-Scale AMRs

Material movement is where most people think automation gets expensive fast. But it doesn't have to start that way.

Take maintenance operations, for example. Your maintenance techs probably spend way too much time walking around looking for tools and parts. A simple solution? Automated carts that follow them around the facility, carrying everything they need. It's like having a really smart shopping cart that knows where you're going.

From there, you can scale up to Autonomous Mobile Robots (AMRs) for moving finished goods, raw materials, or work-in-process items. The key principle here is "parts-to-picker": bringing items to people instead of making people hunt for items.

This dramatically reduces search time and eliminates all that wasted walking up and down aisles. Your team stays focused on the actual work instead of playing hide-and-seek with inventory.

The safety benefits are huge too. Less manual lifting, less exposure to forklift traffic, fewer repetitive stress injuries. Your workers stay healthier, your insurance costs go down, and productivity goes up.

Storage: Start Simple, Scale Smart

Storage automation used to sound intimidating, but newer Automated Storage and Retrieval Systems (ASRS) built for small and midsized businesses have changed the math. You can start small with compact, modular systems—tote/bin mini-loads, shuttle or cube-based solutions, even AMR-integrated racks—that deliver parts-to-picker without massive price tags or years-long installs.

What’s driving the lower cost? Standardized modules, lighter-duty frames matched to your load profile, cloud software instead of on-prem servers, and true grow-as-you-go capacity. Many mid-market ASRS fit in a single bay, run on standard power, and can be stood up over a long weekend. Financing and OpEx options often make the monthly cost look a lot like a forklift payment.

A simple starting point we see a lot: a 200–400-tote ASRS feeding one packing bench. It slashes walk time, cleans up the stockroom, and gives verified picks. When SKUs or volume rise, you add another aisle or lift and keep the same software, barcodes, and workflows—no rip-and-replace.

The real game-changer is the data. Modern storage systems provide real-time visibility into inventory levels, usage patterns, and maintenance requirements. No more surprise stockouts. No more over-ordering because nobody knows what's actually in the storeroom.

A Real-World Example

Take Andrew's production company up in the Northeast. They were facing the same challenges most mid-sized manufacturers deal with: floors that needed constant cleaning, maintenance techs spending too much time hunting for parts, and a storage situation that was getting out of control.

Instead of trying to solve everything at once, Andrew's team is looking at a phased approach. First, they're evaluating robotic floor cleaning for their main production area: the space that needs cleaning every single day but doesn't require much human oversight.

Next, they're considering AMRs to move finished goods from production to the shipping area. It's a simple, repetitive task that currently ties up valuable labor. The AMRs can handle it 24/7 without breaks, overtime, or benefits.

Finally, they're looking at automated carts for their maintenance operations. Instead of maintenance techs making multiple trips to the tool room, the carts would carry everything they need and follow them around the facility.

Three simple solutions. Three clear ROI calculations. Three steps toward a more automated future: without betting the farm on any single massive project.

The Integration Secret

Here's what most people miss: these three functions: cleaning, moving, and storing: work better when they're integrated, but they don't have to be implemented all at once.

Your cleaning robots can be scheduled to work around your material movement systems. Your storage automation can trigger material moves automatically. Your maintenance carts can be restocked by your AMRs.

But you build these connections over time, as each system proves itself and you understand how they work together in your specific environment.

The Bottom Line

Automation isn't about replacing people or installing the fanciest technology available. It's about eliminating the repetitive, time-consuming tasks that keep your team from focusing on the work that really matters.

Whether you start with cleaning, moving, or storing, the key is to start somewhere. Pick the area that's causing the most pain, implement a simple solution, get it working well, and then move to the next problem.

Because at the end of the day, that's all we're doing: making it easier to clean stuff, move stuff, and store stuff. Everything else is just details.

The companies that understand this: that start simple and scale smart: are the ones that actually succeed with automation. They're not trying to boil the ocean. They're just solving one problem at a time, building confidence and ROI with each step.

And that's the real secret to smarter automation: it's not about the technology. It's about the approach.