The Batching Trap: Why Smaller Robots Win

- John Stikes

- 8 hours ago

- 4 min read

A lot of people are thinking about automation wrong.

Most companies buy robots the same way they hire people. They look for capacity.

Power. The ability to handle massive batches in one go.

Here's the problem: robots aren't people.

The Batching Instinct

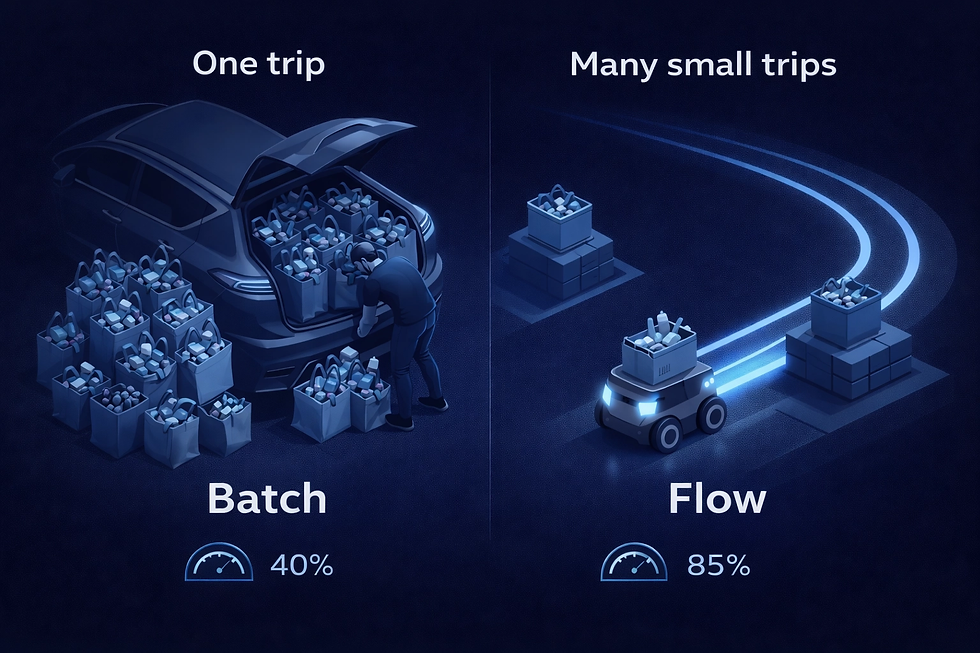

Humans batch work because walking takes effort.

It’s like groceries. You try to carry every bag from the car in one trip. It feels faster. It isn’t.

That makes sense when your legs are the bottleneck.

Robots don’t work like that. They don’t get tired. They don’t care about extra trips.

So stop designing around human limits.

Single Piece Flow Changes Everything

Move one piece at a time. Move it fast. Move it constantly.

That's how robots win.

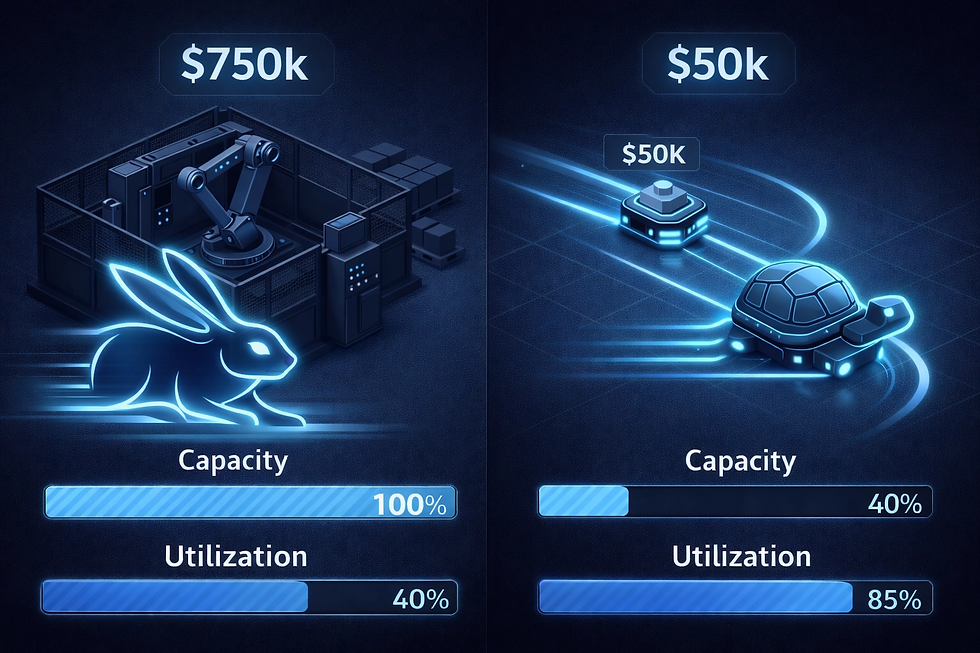

When you batch work for a $750k robotic system, here's what actually happens:

The robot sits idle while you accumulate enough material to justify a run

You tie up cash in work-in-process inventory sitting around waiting

Quality issues get discovered late because you're checking entire batches after completion

Your expensive robot runs at 40% utilization

You bought capacity. But capacity without utilization is just cost.

The $50k Robot That Outperforms the $750k System

Small robots thrive on constant motion.

A $50k mobile robot moving materials every few minutes beats a $750k system that runs twice a day.

Utilization beats capacity.

The big system can handle 500 units per batch. But it only runs when you build a batch.

Two runs per day means it sits idle most of the day.

The smaller robot handles 10 units per trip. But it runs all day because something is always ready to move.

More moves. Less waiting. Lower upfront cost.

Right-Sized Capacity Wins

You don't need a fire hose when a steady stream will do.

Think about it this way:

Big Batch Thinking:

Accumulate 200 parts

Run them all at once

Wait for the next batch to build up

Repeat

Single Piece Flow:

Part finishes upstream process

Robot moves it immediately

Next operation starts within minutes

Continuous flow

One approach optimizes for fewer runs. The other optimizes for maximum throughput.

Guess which one keeps your production moving?

The Real Cost of Waiting

Every minute material sits waiting for a batch to fill is waste. Pure waste.

You're paying for:

Floor space to stage batches

WIP that can't ship

Longer lead times

Bigger quality hits

Meanwhile, your expensive automation sits idle because you’re “saving trips.”

It’s the tortoise and the hare. The hare sprints, then stops. The tortoise just keeps moving. Throughput works the same way.

What This Looks Like in Practice

A mid-sized manufacturer making custom components was running three massive CNC cells. Each cell processed batches of 50 parts. They'd load up the queue, run the batch, then move everything to the next operation.

Their $180k robotic loading system ran 6 hours per day.

They switched to four smaller $25k mobile robots running constant single-piece flow between operations. Material moved the moment it was ready. No staging. No waiting.

No batches.

Results:

Lead time dropped from 3 days to 8 hours

Work-in-process inventory cut by 70%

Robot utilization jumped from 25% to 85%

Total automation cost dropped by 45%

The smaller robots won because they matched the natural rhythm of the work. Parts flowed. Production flowed. Cash flowed.

Break the Batching Habit

Start asking different questions:

Old question: How much capacity do we need to handle our largest batch?

New question: What's the smallest increment we can move continuously?

Old question: How do we minimize the number of runs?

New question: How do we maximize flow between operations?

Old question: What's the ROI on a system that can handle 500 units at once?

New question: What's the ROI on keeping material moving constantly with right-sized automation?

The answers change your entire automation strategy.

The Mobile Advantage

Smaller mobile robots give you something massive fixed systems can't: flexibility.

When demand shifts, you don't reconfigure a $750k cell. You redeploy a $50k mobile unit. New product line? Same robot, different route. Seasonal spike? Add two more units temporarily.

You're not locked into yesterday's production layout. You're not tied to batch sizes that made sense three years ago.

You're flowing material where it needs to go, when it needs to go there.

That's the difference between automation that serves your process and automation that constrains it.

Stop Optimizing for Batches

Your robots don't need to rest. Your robots don't need to minimize trips. Your robots don't care about walking back and forth.

So stop designing your automation like they do.

Move smaller quantities more often. Keep the material flowing. Choose right-sized capacity over impressive capacity.

The $50k robot that runs all day will outperform the $750k system that sits idle waiting for batches to accumulate.

That's not a budget constraint. That's a strategic advantage.

Ready to rethink your automation strategy?

Approach Automation helps companies break free from batching thinking and design systems that actually flow. Let's talk about what continuous material movement could do for your operation.